HOME | DD

Steelseiko — Cast Iron Surface Plate

Steelseiko — Cast Iron Surface Plate

#cast #iron #plate #surface

Published: 2023-01-04 08:50:35 +0000 UTC; Views: 294; Favourites: 0; Downloads: 0

Redirect to original

Description

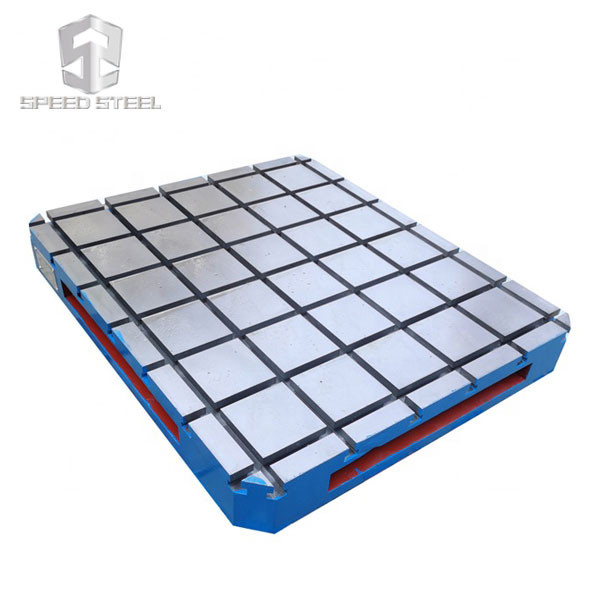

www.steelseiko.com/pro…Cast iron platform is a plane reference measuring tool used for inspection, scribing, measurement, welding, assembly, mechanical performance test, etc. The cast iron platform is divided into 0, 1, 2 and 3 according to the plane accuracy level. Generally, the 0, 1 and 2 cast iron platform is used as the inspection platform, and the 3rd cast iron platform is used as the marking platform.

Cast Iron Surface Plate Parameter

Product name

Cast Iron Surface Plate

Material

HT200-300, QT400-600

Specification

200x200-4000x8000mm or customized (special size can be according to customer requirements)

Structure type

Rib type, box type

Working face

Rectangular, square or round

Surface

V-shaped, T-shaped, U-shaped slot, straight slot, dovetail slot, round hole, long hole, grid line, etc.

Working surface hardness

HB160-240

Surface treatment

Hand scraped, fine milled or polished

Casting process

Sand casting or centrifugal casting

Surface coating

Pickling oil and plastic lining or coating with anti-corrosion paint

Accuracy class

0-3

Painting

Primers and Topcoats

Molding type

Resin sand molding

Operating temperature

(20±5)℃

Package

Standard packaging or as required

Cast Iron Surface Plate Production Process

Pouring

Tempering of Rough Castings

Machine Tool Roughing

Perform Secondary Tempering to Eliminate Internal Stress and Prevent Deformation

Carry out Machine Tool Finishing, and the Overall Dimensions of the Platform Are in Place

Manual Scraping and Grinding for Platforms with High Flatness Requirements

Dealing with the Appearance of the Platform and Packaging

Applications of Cast Iron Surface Plate

In various inspection work, it is the datum plane for precision measurement, used for machine tool mechanical measurement benchmark, checking the dimensional accuracy or shape and position deviation of parts, and making precise lines; it can also be used for product dynamic testing, precision equipment assembly, sheet metal Metal welding and assembly, motor fatigue test foundation, wind power test foundation and other fields.