HOME | DD

HundredHands — Old Bridge: exploded view

HundredHands — Old Bridge: exploded view

Published: 2012-12-17 01:09:12 +0000 UTC; Views: 3743; Favourites: 55; Downloads: 0

Redirect to original

Description

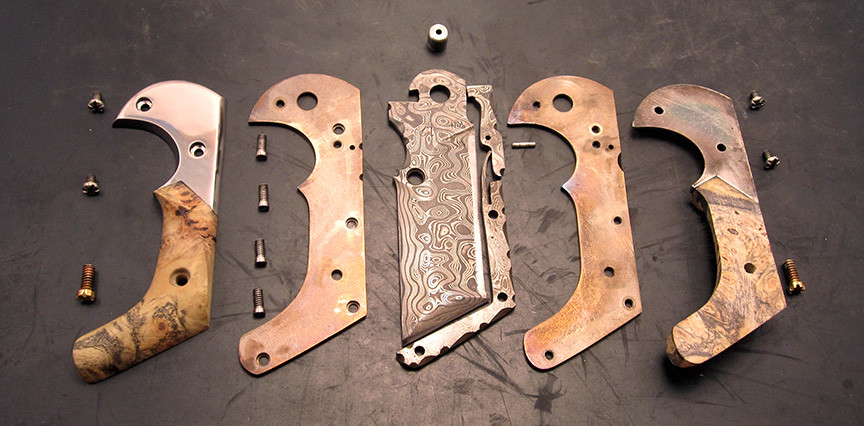

Disassembled.Blade'll be etched one more time before reassembly.

Work in progress.

36 hours in.

Related content

Comments: 36

Thanks! I feel it affords some clarity as to the inner workings.

👍: 0 ⏩: 1

I am hopelessly in love with this design.

👍: 0 ⏩: 1

^_^ It was tricky, pretty tight tolerances in the locking mechanism. I'm happy it worked out in the end!

👍: 0 ⏩: 0

I love these kinds of making-of shots where you can see just how much work and care goes into making something that appears at fist glance to be so elegantly simple. Just gorgeous craftsmanship all around.

👍: 0 ⏩: 1

Thank you, I'm really glad you like it. It was fun to position all the parts like this for you to see the breakdown. I'm coming with some shots from the workshop soon that should give some insight into the work environment and materials and stuff.

Thanks again for your feedback!

👍: 0 ⏩: 0

beautiful work man! slap that bad boy together! I wanna see the finished result! ha ha ha looks amazing!

👍: 0 ⏩: 1

Not long now. Final etch tomorrow and a little fine tuning, then full assembly ^_^

👍: 0 ⏩: 0

I finally have an idea on how tha knives fit together. Thanks for sharing!

👍: 0 ⏩: 1

You're welcome. Some had expressed curiosity about how these are made. I hope to get some decent shots in the workshop later this week.

👍: 0 ⏩: 1

I do have that curiosity. It gives a much better idea on how much work it is and wich skilss you requirer.

Looking in someones kitchen always makes me a bit smarter every time

👍: 0 ⏩: 1

I'm glad!

It's a challenge trying to capture the essence of a physical object in a photo for the internet. I imagine you know all about that!

I hope that images like this are helpful.

Thanks again for your input!

👍: 0 ⏩: 1

Indeed, capturing the essence of an object is really hard to grasp.

This image is very usefull and gives me a much better idea off what you do.

Your welcome, i enjoy it every time.

👍: 0 ⏩: 1

OHA, thats very interessting.

What a Place you thing for the D2? I thing , the guard in the left?

See it big and strong, and a little bit Dieselpunk.

👍: 0 ⏩: 1

The 3 steels I mentioned are actually what's been folded just to make the damascus. The guard/Bolsters are made from 440c. It's made from lots of different types of material! ^_^

👍: 0 ⏩: 0

Wow, you gotta let me know if/when you start selling these. Amazing work.

👍: 0 ⏩: 1

Thank you very much, I will. Hope you're doing well.

👍: 0 ⏩: 0

that metal there is it a mix of various types? it looks like it a lot! oh and ive seen that material on some samurai swords it looks awesome! btw u do all the work like all of your knifes are 100% handmade? per example u could buy the place where ull grab the knife

👍: 0 ⏩: 1

All the pieces are cut from blocks and sheets and billets of material, then sculpted to fit and work together. The steel is actually 3 different steels folded together, AEBH Swedish surgical, D2 and 304SS. The Damascus was folded by Mike Norris.[link] , everything's handmade. ^_^

👍: 0 ⏩: 1

link not found

i see thats great! how do u mold the steel >_> ?

👍: 0 ⏩: 1

oops, sorry about that!

Here you go [link]

The steel is heated in a forge and hammered and folded a bunch, the Blacksmith does that and it makes the beautiful patterns. I get it in the form of a billet, like a long flat bar, and I rough cut the shape I need with a band saw, then shape it down on abrasive wheels.

👍: 0 ⏩: 1

btw this is a hobbie for you? u seem to have loads of materials

👍: 0 ⏩: 1

like a bench saw and all that. u work at home ?

(dont take it wrong im really curious about how u work all that cause my father had this car garage and i used to do loads of stuff in it! but not anymore >_> )

👍: 0 ⏩: 1

Sure, no worries Bud ^_^

I make knives in my Master's workshop on the otherside of the mountains (too much driving, ugh). I'll try to remember my camera to get some pics to share with you next time I go there next Wednesday ^_^ His machine shop is little but he has a small band saw, a nice drill press, grinding wheels and other useful stuff he's gotten together over the past 70 years of his life.

I work as a machinist as my job job where there's lots of amazing fancy pants tools but I can't use those for knife-making

Your dad's shop sounds cool, I hope you find a shop where you can work sometime soon!

👍: 0 ⏩: 1

he still has all the materials on a 20x20 meters storehouse basicly on the forest ahah but we dont get along! u know! u could do a video like an interview about how u work the materials, what are the key parts to make a solid knife! Im a half-designer so i could help u with publicity and stuff even though ure pretty good with photos and drawing yourself xD ure like a Jack of all trades ^^

So how did u end up having a master ?

👍: 0 ⏩: 1

I hear you.

I started out drawing and when I was a little kid. When I was in high school my girlfriend's Mom started seeing this guy who was a knife maker, he saw my drawing and invited me to grind out a blade. Thanks for your offer also! I don't know that's the direction I will go but I'm very grateful for your suggestion, I'm sure you would do an excellent job ^_^

👍: 0 ⏩: 1

woww thats some epic luck! it must be really awesome to be able to create something like that from scratch! have u considered making a sword?

👍: 0 ⏩: 1

Yes, very lucky. It's very satisfying to make these things. I'd love to make a sword but I feel like to do that right one really needs to be a blacksmith. I'm also limited by the size of the kiln we use to harden the blades, my master's is small. My specialty remains the knife that folds.

👍: 0 ⏩: 1

bro i would love to see u doing a sword someday! and i really hope u learn how to do it ! it would be awesome! ure aready a great knifesmith eheheh xD hey! Do a dagger? There are really beautiful ones and i bet yours would be the bomb! and im thinking it would take u less time! How about it?

👍: 0 ⏩: 1

Thanks! Good idea about the dagger. Still, I think a dagger made by me would still be a folding knife ^_^. The kiln in the shop is pretty short, so fixed blades are limited in length. & the folding mechanism is really challenging and fun!

👍: 0 ⏩: 1

👍: 0 ⏩: 1

Thank you & thanks for your suggestion. It's a solid idea ^_^

👍: 0 ⏩: 0