HOME | DD

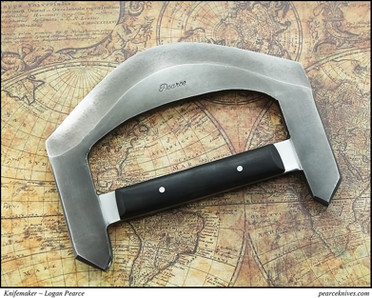

Logan-Pearce — Knifemaking or Blacksmith Forge Tutorial

Logan-Pearce — Knifemaking or Blacksmith Forge Tutorial

Published: 2014-04-14 00:31:35 +0000 UTC; Views: 13795; Favourites: 236; Downloads: 143

Redirect to original

Description

Video: www.youtube.com/watch?v=cP7zIh…Making a coal forge for blacksmithing or bladesmithing. This tutorial shows how my wooden coal forges are made. It doesn't require a welder or anything like that. I find that it is the cheapest way to build a forge, just short of digging a hole in the ground. lol.

I will be using this forge to make most of the knives in my up coming tutorials.

Logan Pearce

www.pearceknives.com

Related content

Comments: 52

Thank you! This does a great job of breaking a starting forge down to really simple low cost basics, just to get started.

Just built mine today, and I'm pretty stoked with how well it works - easily gets the metal hot enough to forge (lost the odd bit to overheating while figuring out how to use it, so there's plenty of heat there). I used coal.

I was able to successfully heat-treat a couple of test pieces (1084), and also have a little play with some very basic forging.

No issues with melting PVC at all, even when turned off. I packed in about 10 cm (4") of dirt, and didn't push the tuyere up much through the base, so it would have been well away from the fire.

I simplified my build of the design for my use:

- No thermal paint

- Friction fit for the tuyere (I already had a stand, so I skipped the legs, and supported the hair dryer with a piece of wood duct-taped to the stand (impatient..) ).

- Used one piece of PVC pipe instead of fittings, and used the hole saw to cut the pieces appropriately to fit together tightly (then duct taped.. Could improve this with glue). This step was a PITA, as the PVC's pretty brittle.

- Used a large round draining spoon (stainless steel) with small circular holes instead of the sink strainer, as I couldn't find an appropriate sink strainer. Cut the handle off, of course.

- Tried duct taping the plug end of the tuyere open, as a stop-gap until I worked out a proper plug. This doesn't work well - coals go through tape, so will need a proper plug (will probably just turn one from a wood scrap). That said, it did still work well enough, so my guess is that the burn through happened after some time had passed.

Complete newbie to this, so still a tonne to learn - but for the effort of putting together some scrap wood, a piece of PVC pipe, a spoon, a hairdryer, and dirt from the back yard, I was duly impressed.

👍: 0 ⏩: 0

Thanks for the video, made the forge this weekend. However, after the 1 hour burn to harden clay, I put in some more coal and decided to bang some metal for the first time, and while the forge was cooling, the pvc melted where it goes into box and fell off. I followed your directions to the letter and it still happened. Any thought on the cause would be greatly appreciated.

👍: 0 ⏩: 0

This article is the reason I joined DeviantArt. And actually this is my first post

I have a small fireplace made out of fire bricks and I'm burning birch (a lot of birch) to get the blades hot enough for quenching. By doing this wooden forge solves a lot of issues. Have to build this next weekend. Thanks again.

👍: 0 ⏩: 1

Welcome! I'm glad you joined. dA is an amazing place to be. It is hard to beat the friends that you will make here.

No problem at all. I am happy to help. A lot of people seem to think that you have to have a metal forge and all that. They don't understand that a lot of blacksmiths long ago actually had wooden forges, when they couldn't make brick or metal ones.

👍: 0 ⏩: 0

I once made a coal forge out of big old building bricks. It looked kind of like an oven. I must say that the temperature rises faster if it's in a partially closed space. Instead of dirt you could use grog clay. Also, you might want to use an old vacuum cleaner instead of hairdryer, it'll last you longer and gives better wind. Just plug the pipe in the other end or it'll start sucking in heat XD

👍: 0 ⏩: 1

This is just for beginners though. I tried to make it to fit people who want to try the craft out for the first time. It seems that with that concept, the less expensive it is to start, the more likely they will give it a try. I also wanted it to be a project that they could put together with house hold items for the most part.

That was what I was aiming for anyway.

👍: 0 ⏩: 0

I love the idea but PVC is Highly Toxic when burned. I think metal tubing would be safer.

👍: 0 ⏩: 1

The pvc doesn't even get warm and none of them have ever burnt. I've been using them for years. Metal is always a better choice. Make sure not to use galvanized steel, bc it is deadly if ever burnt. But again, it won't ever get hot at all. So you should be good with whatever you decide to make it with.

👍: 0 ⏩: 0

hi logan.

great forge.im gonna buildt mine on your specs..

but the one i made dosnt seam to get hot enough,i can get metal to cherry or bright red .but it means a lot of hammering.what can i do to increase the heat...

👍: 0 ⏩: 1

What are you using for fuel and air? The hair dryer should be pushing up enough air to melt metal, mine does. Ask me how I know.

It might be the type of fuel you are burning though. I burn coal, not charcoal, to get it this hot.

👍: 0 ⏩: 0

I think im going to use this method to make my first 'try' at forging a knife. thanks for the upload.

👍: 0 ⏩: 1

As a guy who re-makes his forge every year this is some good work.

Clever use of the PVC by adding a spacer. I usually just use a metal pipe. This could have saved me so much headache.

I have gone to a full brick forge with fire bricks on the inner most layer. I make a long not too wide area for the coal that works real well for the large projects I do. And is much easier to maintain/clean.

I also cover the top with wood to keep the heat in.

👍: 0 ⏩: 0

im thinking i may end up doing this as i have the space in the backyard to start setting up an area to do it. also thought of an alternate use for this forge which would be a small fire bit for late night warmth while star gazing (i live on the edge of town so this is plausible for me ^_^

👍: 0 ⏩: 1

lol! I could be used for that. The good thing is you can move it wherever you want. So if you don't forge for a while, you can just put it up.

👍: 0 ⏩: 1

i know right! its really cool. lookin forward to your tutorials (because of this one picture i've decided i really want to learn this xD)

👍: 0 ⏩: 0

Your very welcome! Keep up the good work!

👍: 0 ⏩: 0

don'T know how long i have been waiting for this! Awesome!

👍: 0 ⏩: 1

I hope it comes in handy!

👍: 0 ⏩: 1

amazing. even if I never to use it, i'd be tempted to make this forge anyway lol.

👍: 0 ⏩: 1

I'm glad you like it!

👍: 0 ⏩: 1

Always love simple home brew solutions, I was impressed with the plastic pvc pipes too, I would have gone copper myself

👍: 0 ⏩: 1

Oddly enough, I don't have copper pipes in this size around my area. I was aiming for the cheapest way for other people. If I didn't want a portable one, I would go with brick for the whole thing and a real blower or bellows. I loooove the way they look!

👍: 0 ⏩: 1

I guess melting pipes wouldn't be an issue since your outside or EXTREMELY well ventilated for the coal anyway.

👍: 0 ⏩: 1

Oh the heat should never touch the pipes. Mainly because the air is pushing the heat away from the pipes. The only chance it would have to melt them would be when you turn it off, but the layers of dirt keep it far enough away that it won't bother it. The blacksmith I knew used only wood and like an inch of clay. He had multiple forges, but for some reason he preferred the wooden ones. lol

👍: 0 ⏩: 0

Wow! What a great tutorial! Thanks for sharing. Logan!

👍: 0 ⏩: 1

Right? I thought it was a pretty fun one.

👍: 0 ⏩: 1

Hey! This is helpful as I've been meaning to get around to making a coal forge soon. (though I want to have a bellows instead of the hairdryer.)

👍: 0 ⏩: 1

Awesome! Bellows are sweet. Especially if you are going for that old time look.

👍: 0 ⏩: 1

Aye I am.

👍: 0 ⏩: 0

get one with a cooling function, or else they burn out with extended use. Just tape down the cool air button

👍: 0 ⏩: 0

| Next =>