HOME | DD

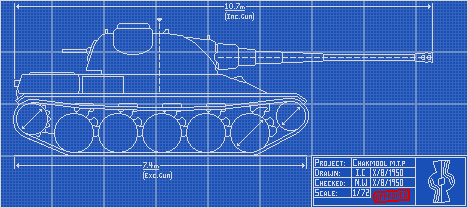

sharp-n-pointy — M40A1 Panther II MBT

sharp-n-pointy — M40A1 Panther II MBT

Published: 2006-04-09 01:33:00 +0000 UTC; Views: 79018; Favourites: 458; Downloads: 378

Redirect to original

Description

SPECIFICATIONS-Crew: 4 (Driver, Gunner, Commander, and Specialist)

Vehicle Armament:

-1x 128mm/L50 High Pressure Freebore Cannon [Main Gun]

-1x 25x185mm DPHA Cannon [Coaxial]

-2x 7.95x50mm MG [Gunners & Commanders Hatch]

-2x5 M20 VIPER Self Defense Munitions Launchers [Sides; Integral]

-2x4 M63 VAR System [Sides; Integral]

-4x4 M3OSD Grenade launchers [Roof; Integral]

Ammunition:

-50x 128mm ALRP RAPID II

-800x 25x185mm

-2500x 7.95x50mm

-20x VIPER Interceptors

-16x VAR Rockets

Length, Gun Forward: 13m

Length, Hull: 10m

Width: 3.875m

Length/Width Ratio: 2.6 to 1

Height Overall: 2.885m

Ground Clearance: 0.563m

Weight, Combat: 78 tons

Weight, Empty: 71 tons

Turret Traverse: 360*

Main Gun Elevation: -10*/+35*

Coaxial Elevation: -10*/+60*

Main Gun Rate of Fire: 10 [15] RPM

Primary Round Type: APFSTDS [Armor Piercing Fin Stabilized Timed Discarding Sabot]

Muzzle Velocity: ~ 2,128m/s

Weight, Complete: 25 kg

Weight, Projectile 9 kg

Penetrator Diameter: 33 mm

Penetrator Length: 990 mm

L-t-D Round Ratio: 30 to 1

Penetrator Material: Tungsten-Cerium-Copper Carbide or TC3 alloy

P-t-W ratio: 21:1 hp/ton

Ground Pressure: 0.73kg/cm^2

Engine: V16C-2000 Hyperbar diesel

Maximum Horsepower: 1650 hp

Maximum Road Speed: 75 km/hr

Maximum Reverse Road Speed: 25 km/hr

Maximum Off-Road Speed: 55 km/hr

Acceleration, 0km/hr to 65km/hr: 26 sec

Maximum Range: 580 km

Fuel Capacity: 2850 lit

Fording: 2.8m (w/o prep) 5m (w/ prep)

Tracks: 533mm Dual Linked Metallic

Vertical Obstacle: 1.03m

Trench: 3.3m

Gradient: 70%

Side Slope:45%

Armour Type: AMTCE Composite w/ CERA V

RHA:

-Turret

Front: 1900mm vs. KE/ 2500mm vs. CE

Rear: 550mm vs. KE/ 1875mm vs. CE

Sides: 1000mm vs. KE/ 2250mm vs. CE

Roof: 130mm vs. KE/ 1700mm vs. CE

-Chassis

Glacis: 1950mm vs. KE/ 2800mm vs. CE

Rear: 700mm vs. KE/ 1950mm vs. CE

Sides: 1250mm vs. KE/ 2550mm vs. CE

Skirt: 550mm vs. KE/ 1275mm vs. CE

Night Vision Equipment: Yes (Driver, Commander, Specialist, And Gunner)

Design Features-

The Panther is arranged in a conical fashion with the Drivers compartment to the center and left of the vehicle. The Gunner in his specialized seat in the center right . Both the Driver and Gunner sit in the center of the turret ring, this position reduces pitch input to the occupants allow them to drive at higher speeds before the dynamic ride level they experience exceeded the limit of 6 watts of average absorbed power in the vertical direction meaning the ability to perform to their full capability during high off-road speeds. The power pack is to vehicles rear separated by an armored fire proof bulkhead. As a supplementary system a 50 liter secondary fuel reserve is also installed incase of the destruction of the primary fuel tanks. To the rear of the driver/gunner area is the engine compartment resting along the midline, and center of the vehicle providing the best balance for the vehicles suspension in order to provide superior mobility as required for long range patrols in the often hostile environment of the republic.

Inside the two person turret the Specialist and Commander sit on either side of the autoloader the Commander separated by an armored bulkhead from the main gun much as the Driver And Gunner are separated from the engine compartment. The Specialists compartment on the left side of the turret is open to the autoloader to allow him to provide repairs or manually load the gun as needed. The bulkheads in the design allows for a higher structural spatiality, and better shock resistance to the vehicles frame due to impact or other stresses. It also provides continued survivability as loss of the autoloader in the more vulnerable turret (compared to the Driver or Gunners compartment.) Does not mean a loss of capability, only a higher work load on that of the Specialist. Likewise, loss of the specialist only prevents the back-up option of hand loading the shells but maintains the lethality of the main gun at full capacity (depending on how the compartment was struck.).

To the front of the turret is the secondary ammunition storage compartment, self sealing fuel tanks and auxiliary power pack which provides supplemental power to the system; allowing for immobile ‘silent’ operation in a defensive stealth role with little to no thermal signature and the ability to passively range and strike an enemy tank the Panther II can make long range kills without the need to expose itself or draw un-needed attention. At the very rear of the tank is the combined Exhaust and Radiator compartment which not only provides a significant reduction in the vehicles thermal signature but the extra bulkhead and equipment allow for better protection of the power pack, and for a cooler exhaust which increases the vehicles survivability. As such a strike to the lightly armored rear of the vehicle is not a lethal hit, though it can significantly lower the tanks capabilities the vehicle will most likely still be capable of maneuvering, returning fire and such long enough to retreat to safety.

Fighting Compartment-

The fighting compartment of the Panther II is a stark contrast to most modern tanks. MPCD’s or Multi-Purpose Color Displays (a device usually found mostly in fighter planes) are mounted in each station allowing for high contrast touch operated full color control stations that allow for smoother and more efficient use of each stations available space, as well as the ability to ‘hand off‘ certain functions should a station become damaged or a major injury sustained by a crew member. This ability allows for increased vehicle lethality even when damaged and short of a lethal strike to the drivers compartment all offensive and defensive functions can be handed off as needed to allow even one person to control the functions of the vehicle (though obviously at a decreased level of efficiency.)

The Drivers compartment at the center left of the vehicle contains a partially reclined shock absorbed seat that makes a smoother ride for the driver as he is the closest to the suspension and most likely to take the most abuse during high speed cross-country travel. To either side of him are MPCD’s that can provide full details of the vehicles current capabilities (speed, fuel, percentage of slack in the tracks, etc). As well as displaying images from the armored rear view camera and passive observation via the commanders sight should he need the additional panoramic view be required. The driver also has his usual three periscopes which provide a 180* panoramic view, with a VISTA sight covering the forward 60* arc to provide all weather day or night driving capabilities with no need for external Illumination.

The Gunners station is very purpose driven, it has two MPCD’s for ammunition selection, autoloader programs and such, but the main work is done with their eyes in the sights, and just like the drivers compartment is partially reclined with the MPCDs and main sight on a sliding system that allows them to be brought forward once strapped into the seat, which means less strain on the gunners back and shoulders and an overall more comfortable shooting position. During a dismount, or entering the vehicle the station is slid back and locks into place so as to not get in the way of the operator.

The Commanders station is situated in the Turret above and behind the Gunners station with the gun bulkhead and autoloader separating him from the Specialists compartment. The Commanders station contains three MPCD’s which help provide navigational and GPS data that can then be transferred in real time to the driver or an entire company allowing for highly accurate deployment of combined arms forces. Attached to the Commanders Helmet along with a microphone for use of both the internal, short range, and long range radio systems; a Commanders Personal display can be pulled down to cover the commanders right eye. This system directly controls the Commanders Individual Thermal sight located on top of the turret, and rotates in conjunction with the commanders head. This system though seemingly complex is converted from an almost identical system in the Apache Attack Helicopter, and allows give the commander increased situational awareness without decreasing his ability to keep a close eye on the other functions under the commanders control. The target selection, lock and unlock of the head following functions, and reticule control are controlled by the commanders right hand via a multi function joystick, and controls the prompts on his personal display, while the left hand is free to use the other MPCDs as needed for navigation, fire control, etcetera. Integrated with the Commanders Personal display is control over a OWS (Overhead Weapons System) which allows the commander to lay down defensive fire without compromising his situational awareness, or exposing himself to battlefield hazards.

The Specialist is located across from the Commander and above the Driver. To most foreign armies the concept of adding a fourth crew member to a tank equipped with an autoloader may seem somewhat odd, but to those familiar with the everyday realities of a tanks life, the specialist is a valued member of the team. Trained as a dedicated vehicle engineer he is the vehicles leading authority on keeping the Panther rolling day or night. When ;buttoned up’ the specialist acts as both the Defensive system operator (he controls the mode and effect of both the VIPER and VAR systems and acts as a back up gunner in the case M-kill or as a loader in the case of an autoloader or power failure as may well be required. The Specialist also has control of an identical OWS to the Commanders increasing the tanks versatility and defensive firepower significantly.

Crew Amenities are provided in order to increase the comfort of the crew while on long patrols but not to the point that it may decrease their situational awareness. Though Spartan the Tank does carry personal water reserves (attached to the later mentioned removal Independent Air System) these are refilled regularly while still attached via their umbilical to the tank or come along with the IAS when bailing out into a possibly hostile (chemical or otherwise) environment is required. Commonly operating in Long patrols in Antarctic conditions the Panther II was equipped with what some consider a ‘darn handy’ creature comfort. Extrapolating on the need for an electric space heat to warm both sets of crew members the Engineers at ATI installed a device many would call odd, but the Tankers of the 7th Armored division call ‘nifty’ comprising of a folding door containing a box shaped hollow and two sets of heating elements (as well as a wire tray for support) allows the crew not only the increase internal heat in the winter time (with door open) but also the ability to field cook their food when the ability to set up camp is neither advisable or possible. This dual use unit can also heat water for making coffee or tea, and contains two storage drawer to either side for condiments and beverage packets.

Protection-

The primary protection of the Panther II uses both Modular and Fixed armor to provide light weight of transport, and still allow for full protection from battlefield threats. Though designed as primarily to counter KE threats it has excellent CE protection qualities that are further augmented by the Implementation of fifth generation Captive Explosive Reactive Armor.

Outer Coating-in the sprit of Zimmerit anti-magnetic paste of the past; the Panther is coated in a matte rubberized polymer spray coating to decrease its UV reflections and to partially distort LADAR and laser rangefinders. Though the technical merit of this application is questionable it does help prevent corrosion and has shown to somewhat decrease the power of direct laser sources for the purposes of target illumination.

Modular Armor-

The outer layer of the composite modular armor helps hold the outer armor together, and allow some slight flexibility yet superior density to engage various threats. Resin impregnated Aramid Fabric is wrapped around the composite armor to allow the best small arms protection, and structural strength. Below the outer layer is the primary anti-tank round stopper a single piece poured Ceramic DCP plate.

The Ceramic Plate is sandwiched between two plates of CVT (Chromium Vanadium Tungsten) Austenic Steel alloy the whole assembly then undergoes a hybrid DCP/Triaxial-prestressing method in which the preformed, porous ceramic material is soaked in a bath of molten metal, resulting in super-dense material. As the metal cools the composite of three plates (one of ceramic, and two of alloy) compresses increase sing both the density and compressibility of the composite dramatically. This process works at relatively low temperatures and therefore, is more economical. The resulting compound can be molded into complex shapes and offers improved protection at significantly lower weight. this by itself is rather effective but its merely part of the whole design.

Below the outer plate are several overlapping Ceramic 'chevrons' these chevrons force any round that happens to penetrate the outer plate to then penetrate the chevrons at a much higher oblique angle than the outer plate increase the armors effectiveness not only by changing the penetrators vector, but by increasing the thickness it has to penetrate. These chevrons are suspended in an elasticized rubber like polymer that reduces the shock to the overall plate and transfers much of the impact energy outwards reducing the stresses on the impact plates. This material also helps break up penetrating HEAT jets, and KE penetrators by causing the chevrons to move around under the force of impact effectively 'chewing' on the round and degrading its overall performance reducing it to little more than spall.

Backing the composite matrix is a second composite Alloy/Ceramic plate forcing the penetrator to again punch its way through at a different vector, forcing the round to fold or break up before it can defeat the final plate. The whole composite is then sealed in a wrap of aramid fibers to absorb any remaining spall and attached to the base armor of the tanks hull in sections for easy replacement .

Base Armor-

In light of the Republics advances in Applications of Thermoplastic resins and advanced materials, it is no surprise that the armor for the Next Generation of Panther Tanks is a byproduct of its continued research. The Monolithic Armor Plate (MAP) for the Panther tank are produced using a process in which sets of inexpensive, thermodynamically compatible ceramic powders [Boron Carbide (B4C) and Titanium-Carbide (TiC)] are blended with thermoplastic polymer binders and then co-extruded to form a fiber. This fiber composite is first braided then woven into the shape of the desired component. The fabricated component is then stacked and pyrolyzed to remove the polymer binder and hot-pressed to obtain the base preformed ceramic material for final processing.

The preformed ceramic matrix is still rather porous, and though its extremely hard and somewhat ductile, it is still rather fragile compared to a The DCP process avoids extensive shrinkage in the processing of dense ceramic parts, works at lower temperatures than conventional methods, does not require the use of high pressures, and eliminates the need for post-process ceramic machining. The preform is then soaked in a liquid metal alloy bath. The preform absorbs the liquid metal like a sponge, and the liquid metal then reacts with the ceramic powder to form a new ceramic compound that fills in pore spaces say. The result is a part with a larger internal solid volume, but the exact same external shape and dimensions as the original preform. The DCP method requires reaction temperatures of only 1,200 to 1,300C, compared to the 2,000C required for traditional methods, to form very high melting point, covalently-bonded ceramics. Because the final part maintains the shape of the original porous ceramic, post-process reshaping is eliminated. This translates to potential cost savings for manufacturers, which have to use pricey diamond tools to shape such parts.

The finished Composite is extremely Dense, Lightweight (comparable to a similar strength material) and is ductile enough to resist severe impact stress, while providing excellent thermal properties and being easy to manufacture and replace when installed in a modular system.

The skirts of the Panther II are Unique compared to any similar system currently in use anywhere in the world. Comprising of a wave style fixed skirt above the maximum wheel travel, the skirt provides full [protection of the main hull and return rollers on the vehicle from both vehicle and Infantry launched Anti-Tank munitions. This non-flexible skirt is supplemented by two diamond skirts that can raise and lower with the road wheels to help provide maximum protection forma mission kill while underway, and yet because they react with the road wheels do not prevent the tank from moving around freely off road.

The crew compartment is protected against anti-personnel mines by means of a reinforced composite floor plate, and beveled edges that deflect the blast from large anti-tank mines outwards. Nuclear, biological and chemical (NBC) warfare protection is integrated in the crew compartment air-conditioning system via collective overpressure and air filter systems. Backup individual masks with independent air supply is standard and is removable in the face of a hostile environment bail-out. The infrared signature is minimized through special exhaust ducting and ‘thermal black‘ resin coating on the internal compartments. The power pack compartment is fitted with a halon fire extinguishing and warning system, which can be automatically or manually triggered by section.

Fire Control and Observation-

The Panther II is equipped with the VISTA all weather vision system provides nearly unlimited sight under difficulty visibility conditions such as dark nights, hard rain, fog, heavy dust etc, without the need for active illumination. The system combines dual-band (visual Imaging Infrared TV (I2CCD) and thermal IR sensor head covering 40x30 deg. A special algorithm combines the two images into an enhanced picture. Color coding is used to highlight specific objects as selected y the commander.

The hybrid turret and gun control system consists of an hydraulic elevation drive and an electric traverse drive. The line of sight stabilization in more than just elevation and azimuth provides high hit probability for stationary and on the move engagements against both stationary and moving targets.

The system has four modes of operation : stabilized mode with the gun axis slaved to the line of sight, slaved mode where the gunner's line of sight is slaved to the gun axis, a non stabilized mode and back-up mode with manual operation for emergency use. A fixed gunner's stabilized 10x VISTA sight with laser rangefinder is assisted by a digital fire control computer to form the primary fire control functions for the Panther II. The digital fire control computer downloads data from the tank's meteorological and wind sensors, together with the tank attitude, barrel wear characteristics, ammunition selected and target data then calculates the fire control algorithms and is used to control the gun, the sighting systems and the laser rangefinder to ensure an accurate shot, and a flawless kill. Though not revolutionary, it is effective, and battle proven.

The commander's station on the right of the turret is equipped with the panoramic stabilized VISTA sight and a OLED monitor displaying the thermal/EO image from the gunner's sight. The commander's sight, mounted on the centerline of the turret, has a 360° traverse and an elevation range from -10° to +60°. A separated laser range finder is also used and the computer is cable of tracking ‘pre-tagged’ for the gunner while the commanders sight is no longer designating. Both the Gunners and Commanders sights are behind a 45° angled semi-reflective polymer cover this prevents enemy vehicles from attempting to blind the Vista sights on the vehicle by means of Laser radiation.

But this is not everything; a stabilized passive computer corrected 70cm thermal stereoscopic coincidence sight. Originally designed to be controlled by an eyepiece, which gives the user two images of the object being measured; when these are brought into coincidence (overlayed) the distance can be read off the scale on the adjustment lever or control. The scale is calibrated to read distance but is in fact a measure of the amount of movement needed to turn a prism or mirror, mounted on the end of a fixed base, to overlap the two images. In the Panthers’ Passive Coincidence sight, the system uses two UV/EO cameras with two prisms on either side of the main gun housing. Because a computer has an easier time overlaying intense UV signatures than natural outlines. To give the fire control computer as accurate as possible passive ranging data. The connection between the servos and prism is a laser sensitive tape that allows for measuring ranging increments to a millionth of an inch of rotation. This ranging data is then is handed over to the computer, where the main sight is properly adjusted for the hit according to the range entered and normal laying data for the weapon. The drawbacks of the system are that acquiring a target while on the move is slower than the traditional method as each readjustment takes time. Ranging while on the move is possible but only of any use at slower speeds as the constant re-adjustment taxes the fire control system. Though not as efficient as a laser system, it is devoid of any signal that the target vehicle is being sighted in for a kill, and allows for stealthy engagement without prior warning to the target should they be equipped with a similar Laser Warning Receiver up to the main guns maximum range and beyond.

Armament-

The main armament of the Panther II is far departure from its predecessor. Where as the original Panther mounted an indigenous SV60A 115mm high-pressure smoothbore gun 60 calibers in length with a thermal sleeve and a semi-automatic gun loader. The New Panther uses a Enhanced Freebore Pneumatic Effect Cannon or EFPEC. An improved EFPEC cannon is quite different than its predecessors which used the somewhat questionably efficient ‘rail and groove’ method which allow for the entire length of the groove to be open to both the front of the round and the propellant gases leading to any turbulence possibly allowing propellant gas to escape and to increase the area that the gas expands into decreasing the cannons overall efficiency when things didn’t go exactly as planned. Replacing this questionable method is a much simpler to manufacture method of one-hundred and twenty canted two centimeters cells four millimeters deep arranged in twelve rows of ten cells. This method allows for a heavy barrel to be drilled out instead of constructed from several individual parts and then constructed into a barrel that is only as strong as the welds that hold it together.

In a normal smoothbore or rifled barrel in a state of rest, it is observably filled with air also in a state of rest. When a round is fired the vacuum generated by the mass of air being distorted by the movement of the round is sucked around the aerodynamic shape of the round (as can be shown in a ram accelerator cannon). The path of least resistance for the first 'block' of air in front of the projectile is to be pushed to the side and the remaining turbulence forces the air into one of the one-hundred and twenty cells. The air remains pressurized in the cells by both physical occupation of space , and air turbulence. This method also prevents propellant gas from behind the round from slipping out as the inner bore is fully occupied by either the sabot or projectile.

As long as the pressure of the main propulsion remained constant (well call this Pressure +2) it would be higher than the air in the cells, but as it reached the end of it pressure +2 phase (as the gas expands along the length of the barrel its ability to propel the projectile drops) and reaches the Pressure +1 phase. The bullet in a normal cannon would begin to decelerate slightly due to friction, but, with the lowered pressure of the main tube in a Freebore cannon the pressurized atmosphere in the cells are now of equal level with the propellant gas (P+1) and would expand removing the pressure gap and continuing applying a steady pressure all along the bullets path along the barrel ([P+1] + [P+1]= [P+2]). The round therefore receives a constant acceleration as it moves along the barrel, it will also have encountered less friction than a full bored gun due to decreased surface area contact, and have a much more accurate shot with a flatter ballistic trajectory (as can be shown via similar Freebore effect weapons).

A normal Electro-thermal Chemical ETC cartridge has a fuse of tapering cross section which enables higher impulse energy to be imparted to a projectile by means of complete controlled burning of propellant. A long, narrow tube filled with propellant has a fuse on its inside surface with a cross section that tapers toward the discharge end, separated from the electrical ground of the cartridge casing by a layer of insulation sufficiently thin to be destroyed as the fuse ignites the propellant. A high-voltage electrode connected at the back end of the tube provides for application of a pulse of sufficient current density to ohmically heat or burn the fuse in a controlled fashion from the discharge end to the back end. A Solid Propellant Electro-Thermal Chemical cartridge as used in the Panther II cannon uses an internalized block of solid propellant (unlike traditional powdered or flaked fillings) and oxidizer poured into the cartridge in much the same way as a rocket does, this system however uses a plasma flash chamber that allows for higher initial peak bore pressures and more consistent burn profiles due to an inward-out burn profile that allows for a larger surface area as the round progresses giving the best performance and consistency for a given shell size. The solid propellant is immune to field temperature changes and operates efficiently even in the most extreme of circumstances.

The Gas Recoil Attenuation Device (or GRAD) is installed uses an unconventional fume extractor to pressurize a pneumatic recoil attenuation device in a fashion similar to a gas delayed blowback mechanism in firearm, however on a much larger scale and with a different purpose. It lowers the total transferred recoil of the gun before it is transferred to the body to be absorbed by the relative mass of the tank allowing the high velocity cannon to put less strain on the overall frame of the vehicle. The gun mount (which mounts both the main gun and the coaxial Dual-Purpose 25mm coaxial Cannon) is stabilized on two axis and can provide a rock solid firing platform while moving at up to 55km/h on open terrain. The long barreled freebore gun can propel a ALRP round downrange at a lethal 2,128 m/s to targets up to 8km even while on the move. At these velocities the 128mm/L50 High Pressure Freebore Cannon can achieve 1500mm+ RHA penetration at 3000m and do it again and again thanks to the high speed autoloader. Installed RFID tags in the projectile allow for the tank commander to designate both a target and ammunition type which will either automatically load the required round in sequence, or prompt the specialist to hand load a round as may be required. The 128/L50 is a weapon of great effect in the hands of a trained Gunner. The gun tube's Effective Full Charge (EFC) life is rated at 1000 rounds.

Of the 50 rounds carried by the Panther II; 10 rounds are loaded in a high speed third generation autoloader. An advanced descendant of the Fastdraw type which can fire that entire payload in just over minute without the need to return to ‘static’ position to reload. The single rotor is mounted directly to the gun carriage and elevates with the gun. The rotor contains five slots each holding two rounds each, allowing for a two round burst to be fired in under 8 seconds for a theoretical rate of fire of 15 rounds, and a sustained rpm of 10 rounds. This system offers full inventory control, by means of integrated RFID tags, optional round replacement, unloading, and misfire ejection.

40 rounds are stored low in the rear of the hull in a reserve magazine designed to automatically transfer rounds from the reserve magazine to the ready magazine. This arrangement makes the entire complement of 50 rounds available without the crew leaving its compartment. This feature is particularly important when the tank is operating in a contaminated NBC environment, where leaving the crew compartment is undesirable. Complete reloading of the Primary Ammunition rotor takes 3 seconds per round and is completely automated. The autoloader compartment in the bustle, as well as the primary storage of rounds is protected by a series of blow out panels (known as CASE or Cellular Ammunition Storage Equipment) that prevent an ammo explosion from destroying the fighting compartment and subsequent death of the crew should a critical hit compromise the bustle of the turret, or the primary reserve.

The main round of the 128mm/L50 gun is the long used and lethally effective RAPID II round. The Reactive Armor Piercing Incendiary round is comprised of a Laminated Tungsten alloy (known as Tungsten-Cerium-Copper Carbide or TC3 alloy) which was designed to provide similar effects of a DU round (Pryophoric, self-sharpening, Super-dense, etcetera) but without the side effects associated with a moderate radiological material. This new generation of armor piercing sub-caliber ammunition was developed to defeat multiple layers of monobloc, composite, fifth generation ERA, motion transfer, and spaced armor targets found on the battlefields of today or the foreseeable future. The flat projectile trajectory and a short flight time significantly increase the hit probability with an increased ability of the ultra low drag tungsten alloy long rod penetrator to defeat armors, even at very long angles of obliquity at extended ranges, makes RAPIDS round the essential choice for vehicle armament.

Supplementing the main gun is a 25x185mm coaxial Dual Purpose Cannon. While mounted on the same stabilizing platform as the main gun it has a separate elevation than the main gun allowing it to elevate up to 60 degrees to engage low and medium level aircraft (both fixed and rotary wing) at ranges up to 3km with maximum effectiveness. The dual feed allows the gunner to choose between Armor Piercing Incendiary, and High Explosive Programmable Air Bursting rounds at will, to provide the best possible lethality against the target. The HEPAB round contains an electronic timer, an ejection charge and 135 cylinder-shaped tungsten alloy bars or sub-projectiles. The electronic timer is programmed by inductive coupling through a device installed in the muzzle of the cannon. The timer initiates the ejection charge which releases and disperses the tungsten projectiles before impact with the target. This powerful coaxial gun was chosen to lessen the strain on the main gun, and provide more effective air protection than an external 12.7mm or 15mm round could provide freeing up expensive 100mm rounds for their proper use in taking out other tanks and hard targets of opportunity.

With the coaxial DP gun opening up the way for lighter armament in self defense (the focus of the external weapons shifting from AA weapons to protection from infantry) the Panther II mounts two self defense weapons, either two S9 LMG in 7.95x50mm, or a S9 and a K30 SAGL in 30x55mm. Instead of the traditional slip ring system the Panther mounts two powered upper hatches that rotate with the gun mount, This allows the two section hatch, and the guns shield to provide a combined 300 degrees of armored protection against small arms and fragments for both the Commander and Specialist. Digital vision blocks allow 360 degree thermal vision, and the weapon can be operated with the hatch closed as an internally operated ‘Overhead Weapons System.’ Both weapons are mounted on a quick dismount pedestals designed as a crew defense weapon should they be forced to bail out and take the weapons with them. This system allows for a dismounting crew to retain some level of defense as well as providing excellent close in support against enemy personnel while mounted.

More than just a smoke system for generating instantaneous cover for retreat, the 4x4 71mm Grenade launchers in the roof of the turret are an integral part of the self defense of the vehicle. Each contains a small geared rotor and three internal launch tubes with a unitary external opening. The three launch tubes can be filled with a variety of munitions from Fragmentation grenades for close self defense, anti-laser aerosol grenades to make it difficult to range and target the tank, or the new M3-OSD grenade.

The M3-OSD system uses the grenades for more than just covering up the visual signature of the tank. The M3 can also be fired in a specific order to divert the enemy missile from its intended target, eventually causing it to fly harmlessly off into empty space. When the system is tied into the VIPER‘s MMW radar. The M3 Omni-Spectral Defensive Grenade used in the system generates a dense smoke screen within two seconds of detonation 10m from the launching vehicle and guarantees the interruption of the line of sight for 60 seconds from the ultraviolet to the far infrared range, as well as decoy effects against electro optically guided missiles. The M3 produces an RCS density is four times higher than standard chaff-decoys and is spectrally adjusted to produce a spectral signature in all IR-wave bands which provides rapid-reaction invisibility against a missile or used as a traditional smoke screen system in self defense against other vehicles. Protection in all relevant wavelengths of the electromagnetic spectrum (UV, EO, laser, infrared, radar) is assured. Short of autonomous systems or battlefield ‘brilliant’ weapons the MDSS has a 58% effective rate of defense against single seeker guided munitions and a 35% effective rate of defense against multi-seeker systems in drawing the weapon harmlessly away from the vehicle.

JD-8 ILCS-

JD-8 Integrated Laser Countermeasures Suite; Consists of a combined Laser Rangefinder (LR), Laser Warning Receiver (LWR), and Laser Self-Defense Weapon (LSDW). Unlike its predecessor the long used but primitive JD-3 ILCS the JD-8 is arranged with the majority of its components below the armor. However like its predecessor it still fires a high-powered laser to directly attack the enemy weapon's optics and gunner.

Arranged in a vertical fashion between the two internal ammo stays of the turret bustle, the JD-8 uses a multi-wavelength beam splitter in front of a high powered laser emitter, which allows for a single high powered beam to be split into multiple beams each with their own coded wavelength. Above the laser and beam splitter sits a nitrogen filled chamber that can be raised and lowered as the battle permits to protect the somewhat sensitive unit from shrapnel and spall. At the top of this chamber sits a cylinder of bullet proof glass rated to 7.62x51 NATO AP protection, this allows for some protection from battlefield hazards without interfering with the suite’s effectiveness. Sitting in this chamber is a conical reflector designed to allow several split beams to be directed at multiple targets up to the LSDW’s highest power. This arrangement allows for multiple sources to not only be targeted (for direction of VARs) or to neutralize several enemy vehicles simultaneously. In this arrangement the ILCS does not require a high rate slewing assembly as the rate of traverse can be nearly at the speed of light depending on the number of beams currently in use.

VIPER Active Protection Suite-

Designed as companion to Second and Third generation CERA systems, the Vertically-Launched Active/ Passive Defense Systems or VAPS (with the extended range [15+m engagements system] known as VAP-ER or ‘Viper’) Designed to be quick to react with as few moving parts as possible. The system is extremely resilient to battlefield stresses without sacrificing effectiveness or forcing un-ideal design changes to a hosting vehicle to accommodate the system. The VA/PS system is comprised of Three Main units; an external dome Ka band radar, an Internal Control Panel and any number of Vertical Launch Units [VLU‘s]. Each launcher provides 360 degrees coverage and weighs 50kg with nine 5kg Interceptors. The system adds 100mm elevation above the armor, but requires no additional clearance under the armor

The Base of the VA/P system is the Vertical Launch Unit which is comprised of the cell partitions and the mounting bases for the interceptor tubes. Each VLU can contain anywhere from 9 to 25 vertically launched Interceptors. Each Interceptor tube snaps onto the mounting bases allowing for date and electrical transfer in order to provide a quick installation of new tubes and lower turn around times in the field or at home. Each interceptor tube is Comprised of the Interceptor munition (or Autonomous Defensive Reactive Munition) the Launch tube, The power spindle (which provides communication to the individual round) and six Boost/Directional charges. The Boost/Directional Charges are comprised of propellant and igniter with a waterproof covering, when the VLU receives a threat warning the Interceptor is Primed (its capacitors are pre-charged) and the designated boost charges are ignited propelling the Interceptor munition out of the tube, immediately afterwards the directional charge is ignited which gives the round its bearing, after which it continues on its way via ballistic track. Each Interceptor is a Smart fused 5kg Blast Directed Fragmentation Grenade which can engage Rocket Propelled Grenades and other Anti Tank munitions fired from close range, as well as standoff AT missiles. It also offers significant reduction of a Kinetic Energy (KE) projectile's penetration capability.

Built around its 3kg Blast Fragmentary warhead, the Interceptor has its own rudimentary processor linked to a Photonic Mixer Device or PMD which is a special solid state semi-conductor diode originally designed for the automotive industry. The infrared light source (provided by four high intensity IR LEDs) illuminates the scene in front of the Interceptor. Based on the differences in the time that the light signal requires to travel back from the various objects in the scene to the PMD, the sensory system computes a three-dimensional image. Every PMD pixel in the detector module simultaneously records the distance readings for the objects ahead of the Interceptor. The detector's field of vision has a horizontal sweep of 32 degrees and a vertical sweep of 16 degrees. The reading rate frequency is 300 hertz, meaning that a 3D image of the scene ahead is formed 300 times a second. Previously, sophisticated stereo camera technology and immense computing power were required to achieve a comparable level of technical "vision" and understanding of the scene in the field of vision. Weight and space restrictions also made fitting such a system into a small munition impossible. Unlike similar radar or RF based systems, the PMD is able to sense the horizontal and vertical spread of the objects it detects instead of just general ‘there or not’ allowing for higher accuracy of target discernment and subsequently higher successful interception rates without interference of ground clutter.

The Tracking/Detection Ka-band radar is comprised in a pair of obelisk shaped arrays to the rear of the vehicle which are strategically attached to the roof of the hull allowing 360 degree detection coverage of high speed projectiles up to 75m away at speeds up to 3 km/s with an optimal engagement envelope between 10 and 15m. The radar weighs 55kg each and is self contained [besides power source] and is designed to take normal battlefield stresses and retain [reduced, but] operational capability with multiple (very few) half inch penetrations of the array. The way they are positioned allow for superior front rear and side protection even when one array has been destroyed.

Operation-

Operated by the separate main control panel or by an integrated system VA/PS has three modes;

Safe- As any explosive system that could be dangerous during non-battlefield transport, it has a safe setting which disengages the power from the launcher, preventing any intentional or Un-intentional discharge of either the warhead or Launching system. This mode also prevents accidentally launched munitions (by means of surface fire, battle damage, etc) from detonating as their capacitors would not have been pre-charged before launch preventing any detonation of the primary warhead.

Active- This is the Primary mode of the VA/P System. Operating autonomously to threats as they appear, the Ka-band radar tracks threats and pre-charges several interceptors for launch. By using six smaller charges in a hexagonal arrangement, each interceptor is capable of being launched in 12 compass directions split into 30 degree segments for 360 degree coverage of the vehicle. Meaning that at any one time regardless of their bearing the vehicle can simultaneously engage as many threats as it has remaining Interceptors.

Passive- The Passive mode is what makes the V/AP system unique among its Active Protective System peers. Even when due to confined spaces, or supporting infantry using the interceptor in Active mode is unwise, or useless, passive mode allows for some protection against Top attack, and downward launched Anti-Tank Missiles including plunging fire and to a somewhat lesser extent mortar fire. The system achieves this by using the launch tube of the interceptor as a barrel, and the directed fragmentation warhead as a sort of large vertical shotgun against possible threats which will intercept or disrupt their operation before they are activated. Though less accurate and somewhat restricted depending on the location of the VLU, it still adds an additional layer of flexibility to a simple but lethally effective System.

Vertical Anti-Ambush Rocket System (VARS)-

Designed as an active offensive system to take out Infantry and Light Vehicle Anti-Tank crews up to maximum 1300m away from the vehicle. Providing a lethal reactive response against enemy anti-tank crews instead of merely taking out the projectile to attempt to take out (or at least threaten) the highly trained crews who perform such missions. Instead of intercepting the projectile itself (ala VAPS) the VARS or Vertical Anti-Ambush Rocket System is designed to take out the launcher or its crew before they are capable of firing off a shot. Mounted In four tube vertical launchers on both sides of the Tank, The VAR system uses the existing JD-8 integrated laser rangefinder/warning/self-defense device installed on most Mekugian vehicles (or any vehicle with such or similar capability) to;

"first use a low-powered beam to locate the optics of the enemy weapon. Once the enemy weapon was located, the power level of the laser would be immediately and dramatically increased. Such an attack would disable the guidance optics of the enemy weapon and/or damage the eyesight of the enemy gunner."

This provides a useable but previously wasted laser reflection that is used by the VAR to home in on the launching site/position via the nose seeker and destroy the manning infantry or launcher. The JD-8 system uses a vertically arranged refracted beam to be able to not only illuminate several different targets simultaneous (with different assigned wave bands) but sue tot eh compact nature of the ‘above armor’ section (mainly the reflector assembly) the system is capable of being retracted to protect it during transit or battlefield damage

Each VAR is about 5 inches long, and 71mm in diameter. Propulsion is provided by a 8 stick smokeless powder rocket motor with direction control as provided by four solenoid controlled ’airbrake’ system at the rear of the projectile. The warhead of the VAR is a 3kg High Explosive fragmentation type and contains 500 steel spheres set in Octagen explosive generating a lethal radius of 15m with a casualty radius out to 100m+. The system is able to operate both reactively or command controlled and can be launched individually or in salvos for a saturation effect.

Propulsion-

The power pack, consisting of the engine and transmission system, is configured for ease of maintenance and are quickly and easily replaced within half an hour to forty-five minutes in the field. The 135° V16- engine generates 1440W (7400Nm) or 1,931 horsepower, and was designed in-house by HHI is a Hyper bar multi-fuel turbocharged air-cooled diesel engine originally intended for the second generation Cougar. The 135° overhead ‘V’ layout makes the engine nearly perfectly balanced with 8 cylinders opposing 8 cylinders in fluid movement, reducing both noise and vibration, both common maladies of modern tank engines. Using psuedo-Conical combustion chambers allows for the highest torque and Break horsepower of any engine in a Mekugian tank yet, and at much higher efficiency levels the tank is able to operate without a governor out to its maximum range without refueling.

Cylinders: 16

Cycle: Four stroke

Arrangement: 135° Overhead V

Displacement: 34,335cm^3/34L

Bore x Stroke: 135 x 150 mm

Horsepower: 1,931 bhp @ 2100 rpm

Torque: 1440W/7400 Nm

Fuel Consumption: 150g/kWh

Dimensions: 2100 x 1500 x 900 mm

Operating Noise : ~85 dB

Cooling; Air-cooled

Fuel Injection: Direct w/ exhaust preheat

Idle: 600 rpm

Weight: 3000 kg

The automatic transmission has a hydrostatic transmission unit and five forward and two reverse gears. The final drive gears are epicyclic in design and provide higher torque at lower RPM than a planetary gear arrangement, as well as increasing the engines fuel economy. The final drives are also connected by a cross-shaft which gives higher power efficiency in turning maneuvers by transferring the power regenerated at the inner track during a turn to the outer track. The track system of the Panther is a dual pin metallic track with rubberized buffer/traction pads using a pair of Integrated locking pins. Each section of track contains several slip rings with a triangular inner cutout. This cutout helps align and retain the pins better over rough terrain and still allows for ease of replacement without compromising strength. The rubberized traction pads of the Panther are much like the treads on a rubber tire and assist not only in on road travel, but also assist in off road travel in rocky terrain or wet ground.

The running gear consists of six dual rubber lined road wheels, with three return rollers on each side and connector type tracks. To help cull the growing drain on the vehicles batteries a regenerative system is installed on the center of the three return rollers. This system helps alleviate the batteries drain, and remains well protected underneath the fixed track skirt allowing for protected and reliable recharging while on the move. The suspension is mounted on the under frame and not on the side frames, so the suspension is separated from the hull. A result of using a decoupled suspension is that the internal noise level is as low as 85dB which is sufficiently low to meet civilian vehicle noise requirements. The decoupled suspension also provides a spaced outer layer which gives improved protection against mines. Allowing the Panther II to withstand a 7kg TNT explosion under a track without significant loss of mobility or the crew. There are disc type brakes, on each of the final drives, integrated by the transmission retarder.

The vehicle's decoupled suspension system is a combined nitrogen gas spring and hydraulic damping system. For weapon firing, an automated series of valves on the nitrogen gas system are closed to provide a firmer hydraulic suspension system meaning better accuracy. Once the main weapons are discharged the nitrogen gas system is reinstated into the vehicle suspension system and the vehicle is ready to proceed across the rough battlefield terrain. The road wheel travel is over 380mm, and the single pin 450mm wide tracks gives superb mobility. Where other tanks would sink into the mud or snow the Panther II swiftly dances across such hazards with little regard to such minor inconveniences.

Related content

Comments: 36

👍: 0 ⏩: 0

Hi Friends please click this link. weight loss Weight loss training guide professionally designed graphics, it's 100% guaranteed!!!

amazon6tech.blogspot.com/2019/…

👍: 0 ⏩: 1

👍: 0 ⏩: 0

Wow. Just. wow you really whent all out on this.

👍: 0 ⏩: 0

The replacement of the M1? Looks good! It looks like you were influenced by the Russian Black Eagle tank.

👍: 0 ⏩: 0

Indeed the artist really did a superb job

👍: 0 ⏩: 0

M40A1 is a Marine issue sniper rifle, but this is just about the best entry of it's sort!

👍: 0 ⏩: 0

very nice and do you think you have a big enough description.

👍: 0 ⏩: 0

Wow.

Just... Wow.

You really though this design through!

👍: 0 ⏩: 2

👍: 0 ⏩: 1

👍: 0 ⏩: 0

Indeed he did that's vary rare for anyone to thoroughly detail anything like this. Let alone a millitary vehicle

👍: 0 ⏩: 0

The german Bundeswehr uses Leopard 2's. I think this is an imaginary, sort of like a follow up to the earlier Panther? But very well made!

It's great!

👍: 0 ⏩: 0

the turret design reminds of the russian cherny orel - black hawk

👍: 0 ⏩: 0

holy crap ! what kinda specs are those man who are you working for ?!!? excelllent work there

👍: 0 ⏩: 0

Heh ... I must introduce you to my friend ... I think that you and him have some similar topics

👍: 0 ⏩: 0

I don't think you have enough info.

This is amazing. Did you do it from lineart, or from scratch?

👍: 0 ⏩: 0

That

Glad to see youMre still alive, by the way. Great design as always, too. ;D

👍: 0 ⏩: 1

Aye, my tanks are FIGHT!... *Cough* anywho, no not dead, I just realized I dont like post anything here... like... ever.

👍: 0 ⏩: 0