HOME | DD

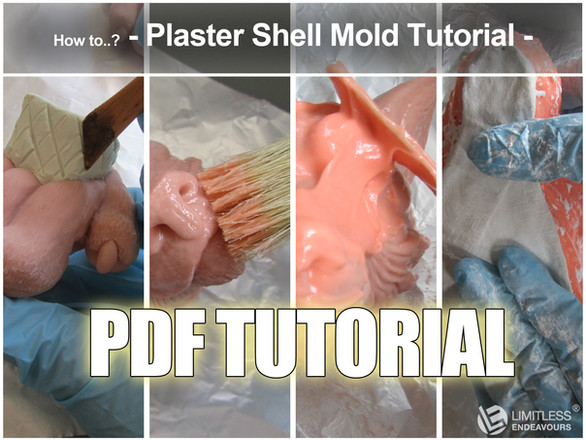

LimitlessEndeavours — Plaster Shell Casting Tutorial

LimitlessEndeavours — Plaster Shell Casting Tutorial

Published: 2014-03-16 02:03:41 +0000 UTC; Views: 15201; Favourites: 297; Downloads: 116

Redirect to original

Related content

Comments: 21

Is there anything special I should do when I demold? I know that the silicone is a lot thinner than on other kinds of molds and I don't want to accidentally rip it when demolding the cast piece.

👍: 0 ⏩: 0

Hello, I was just wondering what the main difference is between this type of mold, and the type you made here:

And when would you want to use each? Would it matter, or do they work the same? Sorry, I've never used resin or created molds, so I have no idea what to do XD

👍: 0 ⏩: 1

The difference between the two is that the plaster shell mold is used for bigger objects that also can feature deeper undercuts. The one part mold is meant for smaller objects, as this type of mold tends to get heavy when poured in bigger quantities. Also, the plaster shell mold is easier to stretch when demolding, as it is just a thin silicone "glove" instead the one part mold is more stiff (and doesn't need shell support when handled).

Hope this helps!

👍: 0 ⏩: 1

Thank you!

👍: 0 ⏩: 0

I noticed you never used a release agent for this part, will the resin not stick to the silicone?

👍: 0 ⏩: 1

No, resin doesn't stick to the silicone. Pretty much nothing sticks to silicone, but silicone itself. When you cast silicone in silicone, I suggest you use a GOOD amount of release agent. I hope this helps!

👍: 0 ⏩: 0

do you know if this would work with clear resin, and if it would stay clear?

👍: 0 ⏩: 1

Yes it works and yes, the resin stays clear

👍: 0 ⏩: 1

nice! thank you

👍: 0 ⏩: 0

Ooh, that tip about using the stir stick as a guide, never thought about that

👍: 0 ⏩: 1

Welcome!

👍: 0 ⏩: 1

Good accidents are the best ones

👍: 0 ⏩: 0

ok, I've got a question....

what type of resin is good resin???

I've only had a go at casting with a clear 2 part (add a few drops of part 2) stuff in a can, and to be honest I wasn't happy at all, it didn't do what was on the tin and some eyes I cast are only now becoming less sticky to the touch (they pick up fingerprints if handled within 3-4 months of casting?!?!)

after this failed experiment I'm not sure what to believe on the different packets :S

but I like this tutorial, makes me believe it can be done easily if you get the right stuff

👍: 0 ⏩: 1

For every project there is a resin that is perfect. You can visit www.smooth-on.com to find the resin that is perfect for your purpose! Clear resins are always a little bit tricky to work with

👍: 0 ⏩: 1

oh neato i'll take a good look at that. thanks

👍: 0 ⏩: 0

Fantastic sharing more of your casting methods! I feel like there's a lot left to question here... so pardon me while I attempt to be specific about what's a bit foggy.

-How do you build the initial mold? In the first image I see how the white middle head should be the casted part, held together with rubber bands. How do you build that part, and where do you decide where to place the seams?

-In the following image something is being poured inside, though how do you decide when things are coated evenly when it's difficult to see inside?

👍: 0 ⏩: 1

This is a continuing tutorial. The previous tutorial shows how to build the mold:

This mold is built to slush cast (means, the mold is turned around in every possible angle) to ensure the resin covers the whole area. If you mold and cast your own project, you will know how to turn the mold while casting to ensure every corner, ear tip, horn or other area is covered in resin. If you don't work sloppy, your cast comes out perfect.

👍: 0 ⏩: 1

And now it all comes together <3 Thank you for clearing that up!

👍: 0 ⏩: 0

for small molds, epoxy putty works in a pinch if you need to build a shell but dont want to run out and buy something you did'nt need

👍: 0 ⏩: 1

Ooooohhhh! Sounds like I have now a purpose for the one bucket Epoxy Putty that I bought too much...! Great tip, Hun! Thanks!

👍: 0 ⏩: 1

heh, right on! In a pinch, I discover alot of different uses of materials that previously weren't suggested

👍: 0 ⏩: 0