HOME | DD

willofthewisp —

Ax, view3

willofthewisp —

Ax, view3

Published: 2005-03-21 06:59:47 +0000 UTC; Views: 20182; Favourites: 611; Downloads: 282

Redirect to original

Description

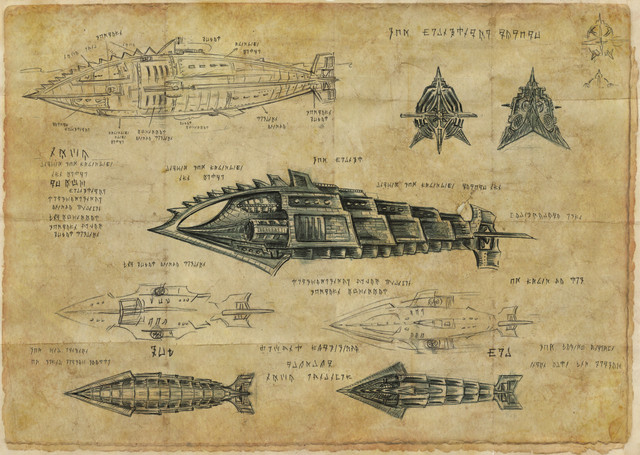

These three pictures are of differnt views of a large inlaid ax, made of steel, and ashwood, and decorated with silver. The patterns on the head were made by carving out channels in the steel, and then cutting them to a dovetail crossection, so that they are wider at the bottom than at the top. I then drew out silver wire to a thickness that would just fit into the channels. Fitting each piece of wire into position, I drove the silver into the channels, so as to cause it to spread out into the dovetail, and become perminantly atached. After all the pattern was so worked I filed and sanded the surface and hafted the ax with a handel I carved from an ash log. The designs are inspired by the inlay work of northern Europe in the 10th and 11th centuries.Related content

Comments: 282

I bet it is. I haven't seen a bow and arrow combo yet. Maybe you can try that? or maybe a crossbow.. since there is more metal involved in that.

👍: 0 ⏩: 1

[link] Here is the picture of that. The bow is Western Yew, the Arrow is white cedar, stained with lampblack, with a forged iron tip, horn knock, and black goose feathers, and the string I made from linen and beeswax. I did not do the die engraving but modeled for the coin with my bow and related gear.

👍: 0 ⏩: 1

Wow.. I wish I had a coin made after me X3 Looks really cool. I want one ^w^ Still the crossbow idea would be really cool.

👍: 0 ⏩: 1

You are right , and a crossbow is something I have not yet made.

👍: 0 ⏩: 1

Beautiful axe! Would look good at my place

👍: 0 ⏩: 1

Thanks. Foe $4,000 it could look good at your place.

👍: 0 ⏩: 0

Amazing work!

It looks indeed like it's saxon or nordic/viking inspired but with your own style. (Big fan of that time)

Keep it up!

👍: 0 ⏩: 1

Forget the baroque the Saxon / Viking period was really the high point of European Art.

👍: 0 ⏩: 1

wow. just...lovely...

makes me think of that song of Bathory.... swing your hammer....way up high...

lovely. i would have this one at home.

👍: 0 ⏩: 1

Wow very hot, never thought I would comment on an axe on this website but hey, yours is beautiful.

👍: 0 ⏩: 1

Thanks, I try to do stuff that is a bit different from the rest of what gets posted.

👍: 0 ⏩: 0

Absolutely gorgeous

Just wondering but do you sell your work?

👍: 0 ⏩: 1

I do indeed. Here is a link to my site.

[link]

👍: 0 ⏩: 0

Amazing!

What kind of animal is in the pattern?

👍: 0 ⏩: 1

Beautiful work. I love the inlay.

👍: 0 ⏩: 1

wow amazing work and detail! Marvelous!

👍: 0 ⏩: 1

I only wish I could be as win as you.

(I would love, someday, to make a sword for my older brother... but how does one even get /in/ to something like that? I mean, how in the world would I find a place that would teach me?)

👍: 0 ⏩: 1

You need to do it. There is a huge blacksmithing community in Oregon, and if you live in the Portland area the guy you need to meet is named Nick, but everyone calls him Grendal. He lives across the river, in Vancouver, and teaches all the time. He is sort of big and scary, but harmless really, and good at what he does. It really just depends on where you live, but I know good blacksmiths in places as small as Takilma, down by Cave Junction.

👍: 0 ⏩: 0

"There was probably an old Viking saying that went something like, 'Axe in the head, early to bed. Axe in the helmet, must be a friend of Helmut.'" --Deep Thoughts by Jack Handey

👍: 0 ⏩: 1

Sounds about right. Thanks.

👍: 0 ⏩: 0

Where did you get the tools for gouging out the lines? What shape tip? What type tool steel? What rockwell hardness, and did you anneal first? How did you achive hardness on your edge after you annealed for the cutting. Or did you cut out, harden and temper and then do the wire?

thanks Robert.

👍: 0 ⏩: 1

OK So many questions. I made the tools out of W1 steel, first shaping them in the forge, then a rough grind, the heat treating them, then honing the cutting surfaces. There were essentially three tools. The first is a little bluntish chisel something like a sculptors rondell that I used to work most of the undercuts, especially on curved lines, which was most of the design. Another tool is a die sinker's tool set up like a flat graver, with the usual foot angle and a rake angel that is a little steeper than I would use on soft metals. With this tool I widened and flattened the bottom of the channels. It is subtle but important than the sides of this tool trail back so that the widest part in the metal is the cutting edge. Otherwise it will drag at the sides and you will not be able to make even the simplest of turns, and will be likley to chip the bottom of the tool as well. The third tool I made like a lozenge graver, with the die sinker's tool shank again. With this one I roughed out lines, worked corners, and did most of the bulk metal removal. If I were doing the project again I would also make steep flat bottomed tool, with a tight trail off, and a short foot for tight corners, a knife edged tool for cleaning up the undercuts, and a small flat inlay chisel. As far as the absolute hardness of these tools goes, well I never bother to check. As long as they are hard enough to do the work. W1 steel is shipped annealed, though I often work it hot so I must take care not to harden the tools until I am ready. They way to go on the ax head is cut, harden, temper, inlay, and it is worth remembering that you can usually spot anneal thin areas like the undercuts by touching a hot iron to them. When inlaying the wire I find that a drawplate is helpful for when you need a slightly different gage of wire for shallow or deep parts of the channels.

I hope the is helpful.

Cheers.

👍: 0 ⏩: 1

Cool and thanks.

I'm a full time swordsmith and have wanted to tackle this for some time. Not had a chance to get a class or watch someone else. Helps the learning curve if you do. I appreciate your help and responce.

Robert.

👍: 0 ⏩: 1

You might want to look at the inlay chapter in The Art of Engraving. It is mainly focused on gold-work on shotguns, but gives a good if roundabout explanation of how to set up tools for gun engraving and inlay.

👍: 0 ⏩: 0

Thanks! You have some nice iron on your gallery as well.

👍: 0 ⏩: 0

Incriedible! What did you use and or do to carve the foxtails?

👍: 0 ⏩: 1

A small hammer-driven graver. Thanks.

👍: 0 ⏩: 2

I make most of the tools that I use for such things from W-1 drill rod. O-1 works almost as well, but for the home studio I generally recommend W-1 as it may be hardened in water rather than in oil which makes a big smoky mess. You can also buy good quality per-made steel gravers from jewelry suppliers. For information about inlay in steel check out the chapter on gold inlay on shotguns in "The Art of Engraving." The book is expensive, but if you can find it in the library, you can read the relevant parts, and photocopy a few charts and diagrams.

Best of luck

👍: 0 ⏩: 0

What type of metal is the graver? Sorry, it's just so friggen beautifull I want to make an ax just like that (different desings ) with my new charcoal forge I 'm setting up! Your ax is just so hawt!!!

👍: 0 ⏩: 0

very nice inlay work! what a wonderful idea, what did you use to cut the channels with? so as to get the dovetail effect.

👍: 0 ⏩: 1

Little hammer driven gravers. Check out the chapter on inay work in The Art of Engraving. See if you can get the book from the library, as it is a bit pricey.

👍: 0 ⏩: 1

oh wow, not my first guess. will see about the book though

👍: 0 ⏩: 0

<= Prev | | Next =>